R&D Office

Since the bags trendy are changing for different markets, such as the new materials development to make bags Eco-friendly, water proof, Flame retardant,etc.So, it is important that we set up our own Research & Development department.

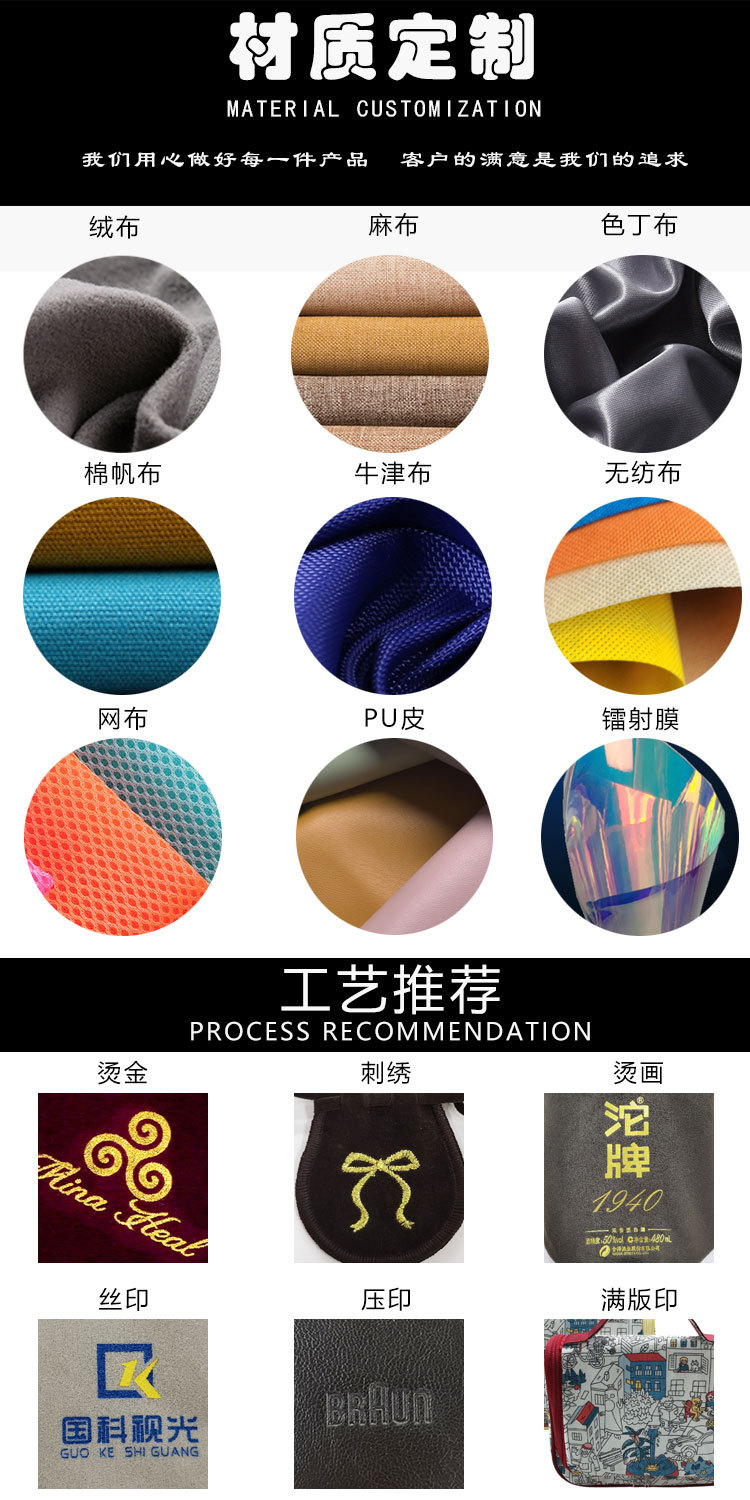

R&D is the initial step in the manufacturing process, where the R&D team determines the key properties of the final non-woven bag, RPET bags, Holographic PVC bags, Fabric with PP with Kraft paper combined materials.

They work on forming a fibrous raw materials into non-woven fabric, PP woven, PVC, cotton and jute combined fabric, or Polyacrylate Emulgion, Pet Film and BOPP Film, cardboard laminated etc. which is crucial for the subsequent

steps in production.

Our R&D department focuses on tying or forming the raw materials into a structure. This involves processes like thermal bonding, which requires heating to stabilize the bond with thermoplastic fiber. The fibers in the half-knitted woven bag

act as thermal binders, using latex or resin binders.

Finishing and Converting is a critical stage where the non-woven bag is given its final touches, such as lamination and customization. Our R&D team ensures that the product meets quality standards and is eco-friendly before it reaches

the customers. Overall, Wenzhou Huichuan Technology Company's R&D department is responsible for innovating and improving the manufacturing process, ensuring product quality, and developing new products that meet market demands and

Eco-friendly environmental standards. Our R&D department play a crucial role in the lifecycle of non-woven bags, PP woven bags, food pet bags, denim and cotton canvas fabric bags, from concept to customer.

Subscribe for our latest Updates

Stay up to date with the latest news, announcement and articles.

- Contact Us

- Century Ave,Xiaojiang Packing & Bags Industry Zone , Wenzhou City, 325042 China

- +86-0577-63055555

- sales@hcnonwoven.com

- BagHome.VIP@gmail.com

- +86 18058831306

En

En Es

Es Ru

Ru Cn

Cn